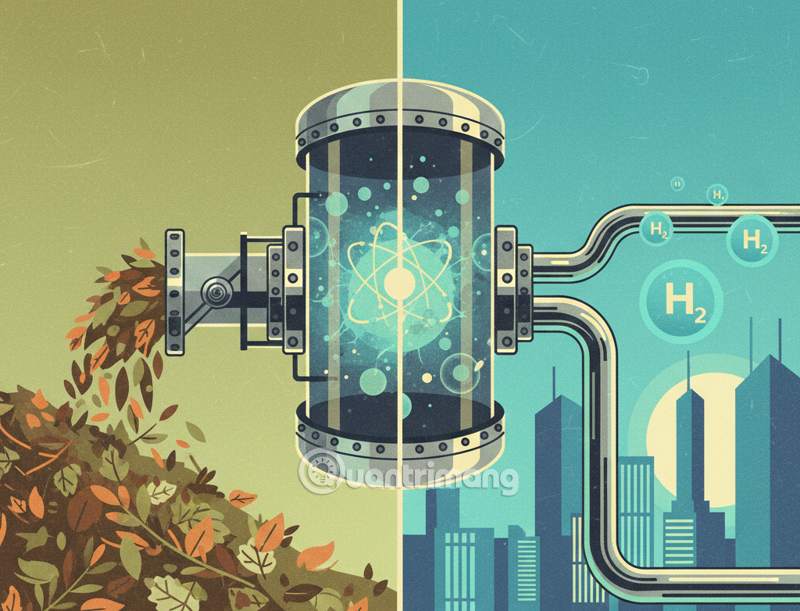

Transforming plant waste into catalysts for producing clean hydrogen.

Researchers have developed a new catalyst from renewable plant waste that promises to significantly boost the production of clean hydrogen. This material utilizes carbon fibers made from lignin combined with nickel oxide and iron oxide nanoparticles, dramatically improving efficiency and durability in the water electrolysis process.

Lignin is one of the most abundant natural polymers, often discarded as a byproduct from the paper industry and bioreactors. Instead of burning it to obtain low-energy heat, scientists at Guangdong University of Technology have converted it into carbon fiber through electrospinning and heat treatment.

This structure creates a carbon skeleton that conducts electricity extremely well, acting as a support for the metal oxide particles. The new catalyst has been named NiO/Fe_3O_4LCFs.

In water electrolysis, the oxygen-releasing reaction (OER) is often the biggest hurdle because it is slow and energy-intensive. However, according to research published in the journal Biochar X , this lignin-based catalyst has solved that problem:

- Low overvoltage: Only 250 mV is needed to achieve a current density of 10 mA/cm².

- Impressive durability: Operates stably and continuously for over 50 hours at high current density.

- Low cost: This is a perfect alternative to the rare and expensive precious metals (such as Iridium or Ruthenium) that were commonly used in the past.

"Our work shows that lignin-based catalysts are not only highly reactive but also exceptionally stable, opening up a more economical path to large-scale hydrogen production," shared author Yanlin Qin.

Under a microscope, scientists discovered that nickel oxide (NiO) and iron oxide (Fe₃O₄) form a nanoscale heterojunction inside the carbon fiber.

This structure helps:

- Bonding optimization: Intermediate molecules in the reaction adhere and detach at the most ideal rate.

- Increased charge transfer speed: The nitrogen-doped carbon lattice allows electrons to move faster.

- Anti-caking: The carbon fiber framework prevents metal oxide particles from clumping together – a common problem that reduces the lifespan of conventional catalysts.

Utilizing globally available biomass to produce energy materials not only helps reduce the cost of hydrogen production but also aligns with global efforts to protect the environment.

Author Xueqing Qiu emphasized: "Our goal is to create a catalyst that is not only effective but also scalable for industrial production based on sustainable raw materials."

This method can be applied to a wide variety of metal combinations, opening up opportunities to design the next generation of electrochemical catalysts from abundant natural resources.

You should read it

- ★ Renewable energy 'goes beyond' all forms of new energy generation

- ★ What is hydrogen water? What does hydrogen water do for health?

- ★ The catalyst can turn carbon dioxide into plastic

- ★ Without electrolysis, splashing a microwave into the water is also capable of generating hydrogen

- ★ Scientists have discovered a way to convert CO₂ into a valuable fuel source.