China develops new method to produce 98% oxygen from CO2

A research team from Nanjing University in China has just announced a new electrochemical device that can directly split carbon dioxide (CO2) into pure carbon and oxygen. This technique promises to bring benefits in the efficient production of oxygen in harsh environments, such as underwater on Earth and even on Mars.

The CO2 to O2 conversion rate achieved by Chinese scientists is impressive.

What makes this device unique is that it does not require the stringent pressure and temperature conditions typically required for similar reactions. If the power source is renewable, this method opens up new avenues for carbon neutrality.

With the benefits it brings, this is a practical solution to control oxygen production from CO2, with potential for wide-ranging applications in many fields, from Mars exploration, oxygen supply for astronaut suits, to underwater life support, breathing masks, indoor air filtration and industrial waste treatment.

Plants use photosynthesis to convert CO2 into oxygen and glucose, relying on hydrogen atoms as an intermediate. For years, scientists have struggled to replicate this reaction artificially under normal conditions. So the new breakthrough from Chinese scientists is very promising, especially since the new method can produce up to 98.6% oxygen.

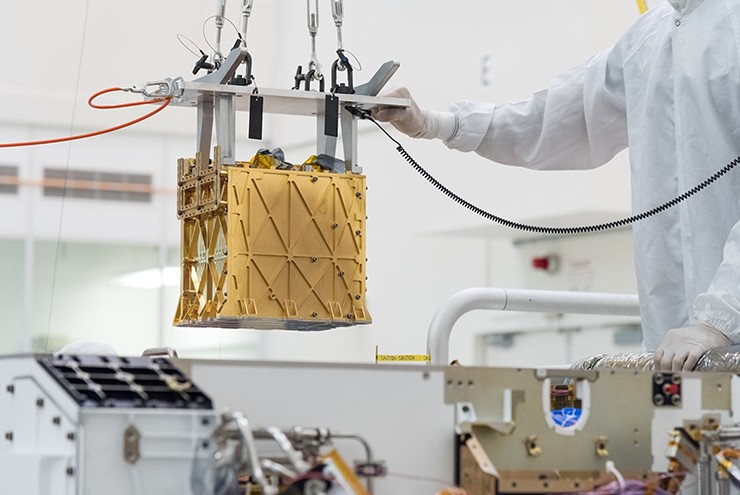

To achieve this feat, the team from Nanjing University collaborated with Fudan University to develop a new technique that uses lithium as the main medium for CO2 separation. The new electrochemical device is designed with a gas cathode using nanocatalysts made from ruthenium and cobalt, along with a lithium metal anode.

The device works as follows: When CO2 is introduced to the cathode, it undergoes a two-step electrochemical reduction process using lithium. First, CO2 reacts with lithium to form lithium carbonate (Li2CO3). This lithium carbonate then reacts further, producing lithium oxide (Li2O) and elemental carbon. Finally, through electrocatalytic oxidation, lithium oxide is converted back to lithium ions, releasing oxygen gas (O2) as a byproduct.

The optimized catalyst achieved an oxygen yield of over 98.6%. The team stressed that 'The use of the optimized RuCo catalyst allows for very high O2 yields, far exceeding the efficiency of natural photosynthesis'.

This new CO2 separation technology also demonstrates versatility in operating effectively not only with pure CO2 but also with a variety of mixed gases, including simulated exhaust gases and a simulated Martian atmosphere.

Mars' thin atmosphere is mostly carbon dioxide, with a pressure just one percent of Earth's. To test the technology, the researchers created a gas mixture of argon and very low concentrations of carbon dioxide (1%). However, the team has not yet announced how much oxygen was produced under Mars-like conditions.