High-class electrical system helps release polluted wastewater

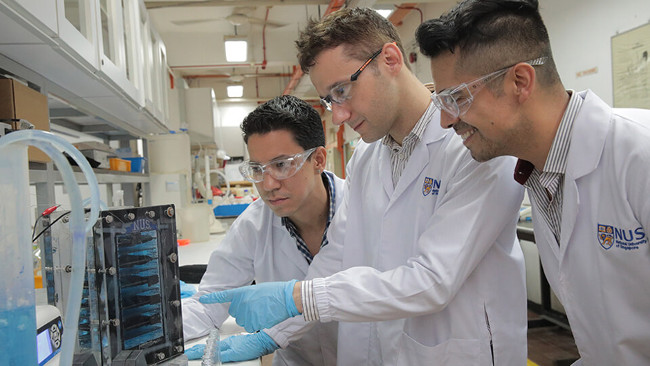

Scientists from the National University of Singapore have developed an electrochemical method to treat industrial wastewater, using electricity as a pure substance for cleaning.

NUS believes that this method can eliminate up to 99% of difficult-to-treat organic compounds, found in different types of industrial wastewater. Furthermore, the system is supposed to operate with low power and does not produce secondary waste such as mud, which does not create more excess waste such as burning.

"Despite significant progress in wastewater treatment technology, the removal of refractory organic compounds is still a costly and challenging process. Our invention provides a solution. It is environmentally friendly and helps to raise the standards of industrial wastewater treatment , ' said Professor Olivier Lefebvre, researcher of the Department of Environmental Engineering of the NUS Department of Engineering.

Wastewater from the electronics and pharmaceutical industries may contain a large amount of complex solvents and mixtures, while waste water from agricultural land may contain a large amount of pesticides or drugs. herbicide. These organic compounds are not biodegradable and can be harmful to humans and the environment.

"Our electrochemical system has shown that it can achieve complete mineralization of any organic contaminants. This means that the system can completely remove organic compounds in wastewater by decomposing them into water and carbon dioxide.

This new system can also be combined as a pretreatment method for an existing wastewater treatment program. It works with low power and this system can be easily combined with solar energy and other refining methods such as membrane use and biological treatments, " Asst Prof Lefebvre.

The system was developed by NUS scientists using electrochemical to treat water and wastewater and does not require additional chemicals to be added to this system.

Processing begins with the pumping of sewage into the system chamber. When electric current passes, the electrodes in the chamber produce hydrogen peroxide and the hydroxyl radical (a strong oxidizing agent) reacts with complex domestic organic compounds.

Hydrogen peroxide is produced and hydroxyl radical is used completely in the process and they continuously break down complex compounds into simple molecules, until all organic contaminants are decomposed. .

For industries that require higher quality water for their processes, the demand for ultra-clean water and maximizing its reuse is also escalating. The global recycling and reuse market has reached nearly 12 billion dollars in 2016 and is expected to reach more than 22 billion dollars by 2021.

See more:

- New thin batteries, protect the environment and work by . saliva

- How to protect skin from UV rays while indoors?