Water can 'cut sweet' concrete and steel. Do you believe that?

It is hard to imagine that "soft" water can penetrate steel and concrete. Even water can cut and shape hard materials such as electric flame cutting machines, laser and plasma cutting machines. Why can water do that?

This is a hydrodynamic method known as Water Jet Cutting - WJC. That is, water rays are created at extreme pressure to process (cut and shape) materials.

Hydrodynamic machining is also called waterjet cutting.

With a huge pressure valve system, scientists have created a hydrodynamic processing machine that acts as an extremely sharp saw, cutting lots of materials sweetly without generating heat. .

The water used to cut materials with pressures from 100 to 620 MPa, the speed of spraying water is extremely large, from 400 to 1,000 meters per second can "cut sweet" steel, stainless steel, concrete . with extremely high accuracy.

In order to shorten the construction time with thick and hard materials, people have mixed a number of other ultra-fine substances into the water so that the cutting process takes place faster.

This cold cutting method is not limited by the thickness of the material to be processed , it can cut thick objects up to 20 inches (about 50.8 cm).

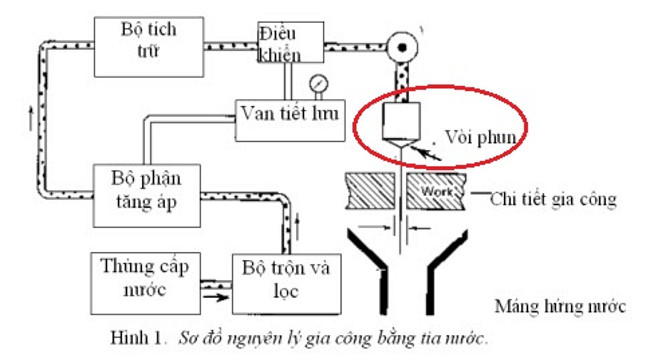

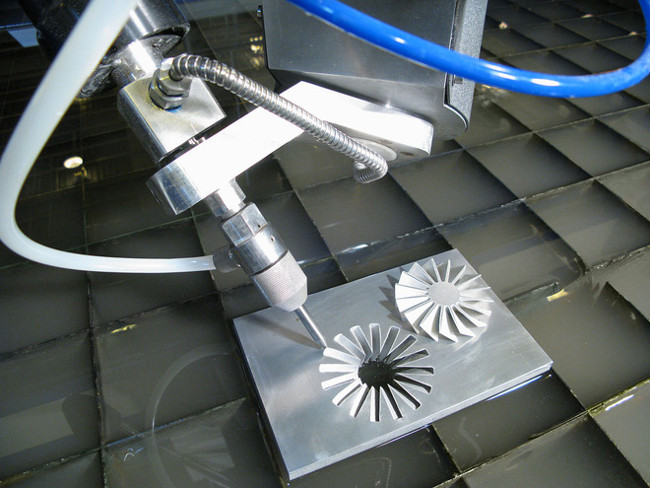

See the operating principle of the cold cutter through the image below:

Picture: Cadcamcae.edu.vn.

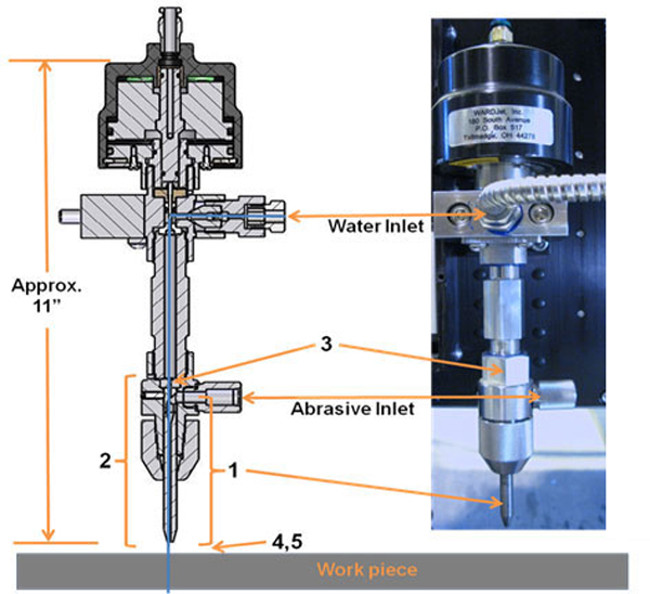

Structure of nozzle.(Photo: Thaodocongtrinh.vn.)

Mohamed Hashish, an Egyptian-based scientist invented this cold cutting method in 1970. At the US laboratory, Mohamed Hashish devised the use of high pressure and increased grinding particles (mixed). Add in water) to increase the ability and time of water cutting materials.

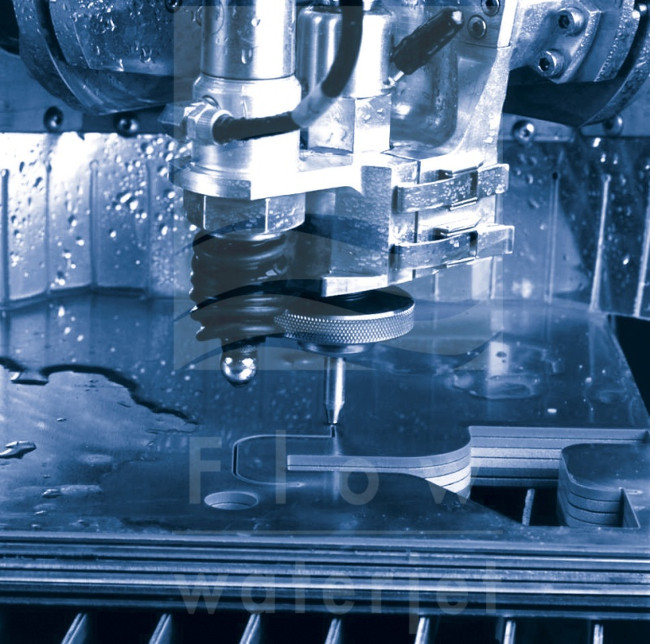

Dr. Mohamed Hashish experimented with a waterjet cutting machine at the Flow laboratory in the US.

After 10 years, with the advantage of not producing heat, processing in many complicated surfaces, creating art form more easily than other heat-generating methods, processing with high precision, flat surface . cold cutting machining method is widely applied in a wide range of aviation, food, automotive, metallurgical, machine-building, visual arts .

In addition, waterjet cutting does not alter the internal structure of the work material and does not heat up the work zone of the material, making the material after cutting is not broken, changing properties.

Currently, this cold cutting method has not been used much in Vietnam due to the high cost of equipment.

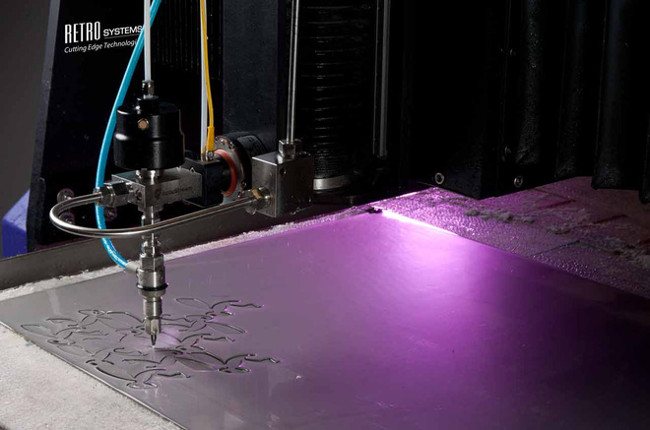

Super-sweet material cutting screen of water jet cutting machine.Video: DaltonsWadkin / Youtube.

Artistic shapes after materials are cut with water jet:

You should read it

- ★ Which iron cutter selects a good brand between Bosch, Makita, Maktec and Total?

- ★ 5+ Cheap iron cutting machine less than 2 million VND is rated the most

- ★ Pocket address to buy cheap brick cutting machine, genuine reputation

- ★ Pocket address to buy genuine, cheap cutters in Hanoi and Ho Chi Minh City. HCM

- ★ Buy any kind of wall groove cutter?