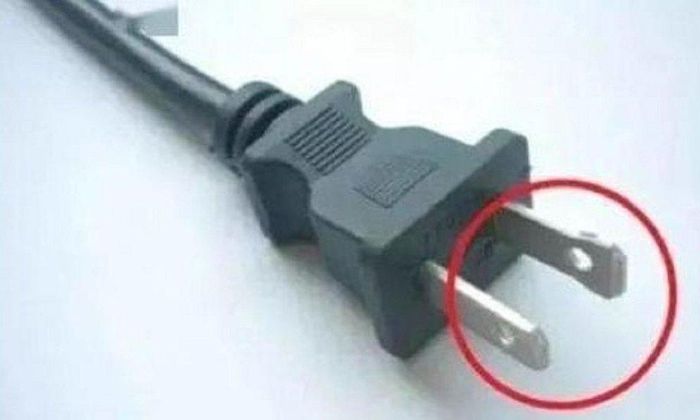

The reason is that there are two round holes on the flat power plug

Before reaching consumers, any product is carefully researched, tested and edited to achieve the perfect design. Therefore, no detail on the object is redundant, it's just that the user does not know its effects.

If you look at the flat power plug, you will see 2 round holes in the metal plug. Many people don't know what the flat electrical plug with two round holes is for.

In fact, these two round holes will help the plug stay fixed and more secure. Inside a standard electrical outlet, there is usually a raised part that fits tightly into this round hole, helping the plug pins contact more firmly with the two metal bars inside the socket, minimizing the risk of exposed pins and electric leakage. . Therefore, flat plugs are one of the ideal choices for families with young children.

These two round holes will help the plug stay fixed and more secure.

Previously, people designed stamped indentations on the socket pins. However, this method can easily cause friction when inserting the plug into the socket and cause a short circuit of sparks. Using perforated holes will help minimize friction when first plugged in, avoid short circuits, and be safer for users.

Manufacturers also take advantage of the two holes at the plug's base to attach seals, helping consumers distinguish between new and used goods.

In addition, these two round holes, although small, still help manufacturers save a significant amount of steel, especially in large-volume production lines.

The holes in the flat plug prongs were the creation of Harvey Hubbell Jr., who worked hard to find a way to make the plug easier to insert into the socket. His initial solution was to add small indentations inside the plug pins; they will come into contact with protrusions inside the socket. Eventually, the indentations were replaced by holes, although the basic idea remained the same.

Basically, there are only two types of flat-pin electrical plugs that use perforated pins: Type-A plug with two flat pins; Type-B plug with flat pins and a round anti-shock ground pin. These types of plugs are popular in the US, Canada, Japan and some other countries. This standard is also known as the NEMA standard.

Meanwhile, in many other European and Asian countries, round pin plugs are still more popular and this type of plug does not need to have holes, because the round pin and round socket design provides better grip. .