Close-up of how the medical mask production line operates?

Before the complicated evolution of the COVID-19 epidemic, medical masks became a familiar tool in daily life and were sought by many people.However, the type of mask is made and how it is produced, not everyone knows it.Let's take a close look at how the medical mask production line works to raise our awareness about this health protection product, as well as to know what kind of medical mask is the best quality. quantity.

content

- What is a medical mask?

- How does the medical mask production line work?

- How to identify a quality medical mask?

- Note when using antibacterial cloth mask

What is a medical mask?

Medical masks are a type of protective mask specialized in medicine, used to cover the face (usually nose, mouth) to prevent the wearer from being infected with bacteria, diseases, Dust through inhalation.Medical masks are used extensively in health facilities, providing doctors, nurses, nurses, forensic examiners . especially those doing surgical work.Medical masks are usually indicated for use in the following cases:

- When there is a state of splashing, splitting, spraying body fluids that carry bacteria, pathogens . affecting the surrounding.

- When near sources of body fluids from a distance of 1.5m or less.

- When working in aseptic environment such as operating room, isolation room .

Medical masks have three main effects: to prevent dust, to prevent chemicals (including car exhaust) and prevent microorganisms.

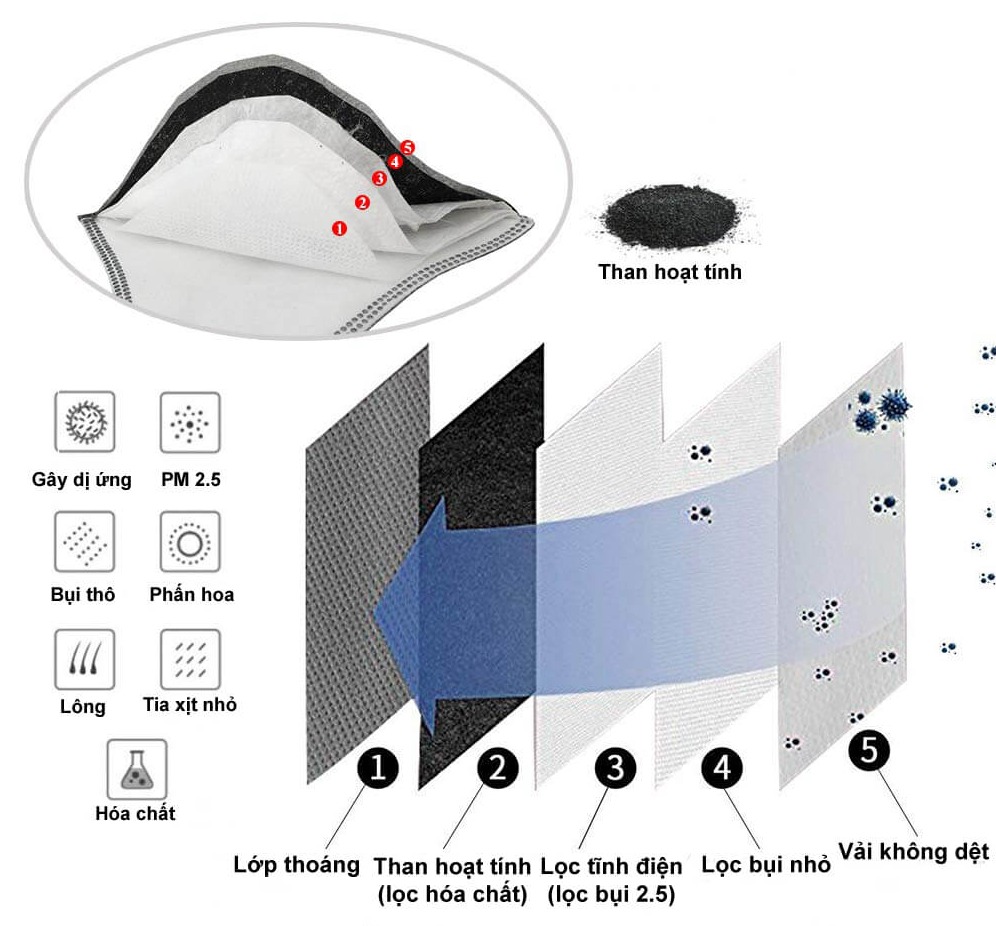

Materials for making proper medical masks include: non-woven fabric, antibacterial filter cloth, if the mask is an activated carbon medical mask, there will be an additional layer of activated carbon filter paper to help adsorb gas, toxic gases in the air, effectively preventing dust, ensuring safety for respiratory system.The materials will be arranged in order by a standard medical mask production line and sewn into a complete mask.Specifically how this line works, we will learn together in the next section of the article.

How does the medical mask production line work?

Standard medical masks used in medical work usually have 3 to 5 layers, including the main components are: non-woven waterproof outer layer, antibacterial filter layer can have from 1 -2 layers (including PM2.5 electrostatic precipitator and ordinary dust filter), activated carbon filter cloth (if any), finally a nonwoven fabric with hygroscopic properties to prevent secretions From the mouth, nose is released into the environment.

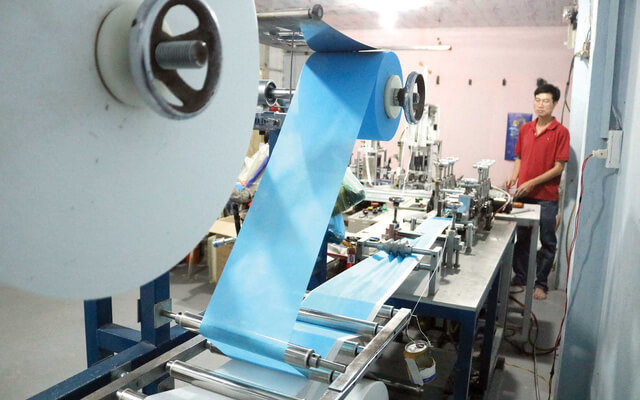

The layers of a medical mask will be fitted to the large rotating shafts on the medical mask making machine and then pulled in and arranged in axes on a dedicated conveyor.Here, the material strip will be passed through a part that helps create folds on the face of the mask, this fold will reduce the size of the mask when it is flat and can be pulled out to adjust the size as you like. according to each face.

In parallel with this process, a sewing machine (stamping) will add a small metal bar to one end of the mask horizontally and sew the stamping edges horizontally again.This piece of metal works to keep the edge of the mask close to the nose of the wearer, ensuring that the secretions from the nose and mouth will not be able to shoot out, nor ensure dirt, bacteria do not follow. nasal bridge slits into the mouth, nose of the user.

After creasing, the material of the medical mask will be pushed through a cutter. Here, the machine will cut this material strip into small masks according to the size already installed and pushed on the conveyor belt, transferred to the sewing machine is waiting.

At the next stage in the production line of medical masks, masks after being shaped and chopped will be transferred to edge sewing machines (stamping) to conduct stitching to close the border and add a strap.The strap of a medical mask may be spandex or nonwoven and can be stretched and adjusted to suit different faces.

At the end of the production process of medical masks, the workers will put the prescribed number of masks into the plastic bags and put them into paper boxes and pack in accordance with the prescribed standards.

Close-up of the medical mask production line

How to identify a quality medical mask?

During the outbreak of disease, medical masks are always a product of the group 'demand exceeding supply' so there is no shortage of people who take advantage of sensitive time to make personal investments, produce poor masks. quality.To ensure yourself and your loved ones when using this medical product, you should note a few ways to identify quality medical masks below:

- Quality medical masks must be at least 3 layers or more, with plastic or metal rods for fixing the nose, strong straps, designs covering the nose to the chin, holding the face close.

- Want to check a good medical mask or not, consumers can also test by dipping in water.Because according to TCVN 8389 - 1: 2010 standards, good quality masks and standard quality must be a waterproof mask, if it is of poor quality and should not be purchased.

- The most important thing is that you should buy medical masks from famous, reputable, originated brands, production batches, production dates, expiry dates, certificates of achievement printed on the products clearly. .Can be purchased at genuine distribution stores, pharmacies, supermarkets and should not be bought on the sidewalks, grocery stores, water shops, online shopping shops on social networks .

Currently, according to the Ministry of Health, not all cases require a medical mask.Medical masks are recommended only for physicians, officials, health workers working in special areas such as isolation areas, surgical areas, sterile laboratories . or patients. have a history of respiratory disease, are in isolation, medical monitoring, family members of patients in care in special areas . For healthy people, the Ministry of Health discourages the use of medical masks anytime and anywhere that should only be used when outdoors, public places, working in polluted environment .

Moreover, medical masks are characterized by a one-time use, if used indiscriminately, not only causes scarcity of resources of health forces but also discharges a large amount of waste. bad influence on the environment.Therefore, at present, the Ministry of Health of Vietnam encourages people to use antibacterial cloth masks that can be reused many times to save costs and reduce medical waste into the environment.

The current high-class antibacterial cloth masks can remove 80 - 90% of bacteria, viruses after 1 hour of exposure and reduce to about 60 - 70% effective after a number of washings (after 10 to 30 Washing times depends on the type of antibacterial used on the garment).With this ability, an antibacterial cloth mask will protect you from the risk of infection if used properly.

Note when using antibacterial cloth mask

To use the most effective antibacterial cloth mask during the season, you need to note a few things:

- Select quality masks, with 2 or more layers (with one layer is large antibacterial and one layer is normal fabric) to prevent the penetration of bacteria and viruses.

- When removing the mask, do not touch the outer surface of the mask with your hand, as viruses and bacteria may remain on it.The correct way to remove the mask is to hold the strap and then remove it from the ear.

- After removing the mask, you should immediately wash and sanitize your hands.If you don't wash immediately, wash your hands clean with antibacterial soap ordryhand soap.

- With a used cloth mask, wash with soap and dry in the sun before reuse.At least 1 day you should change washing masks once, avoid using cloth masks on the 2nd day.

The information we share in the article hopes to help readers approach and better understand the current medical mask production line.Hopefully, you and your loved ones around will choose the appropriate mask product and use it properly to fight the disease together with the whole country.

You should read it

- ★ How is the structure of 2-layer, 3-layer, 4-layer and 5-layer medical masks different?

- ★ Photo: All types of anti-virus masks

- ★ Why are medical masks in black, white, gray, pink and blue different?

- ★ Why does Apple have millions of masks to donate to the medical force?

- ★ China applies jet technology to create masks