Why the foundation of the world's tallest tower Burj Khalifa must be powered 24/7

The foundation of the Burj Khalifa tower is a structure with an impressive depth of 10 stories with a raft foundation about 3.7m thick. This raft foundation was a difficult task mainly due to the large amount of concrete that had to be poured in one block. Engineers will first place the reinforcing bars, and then pour the concrete. Due to the 40 degree heat in Dubai, this work had to be done at night and had to mix concrete with ice blocks while pouring. The process of concreting the entire foundation of the raft, is done in 4 separate parts, each part takes place in 24 hours.

Bill Baker, the chief design engineer of the Burj Khalifa tower, faced many other challenges. First, the biggest challenge is the settlement of the soil. When building conventional structures, engineers always find hard strata, the hard layer of soil on which a building can sit. During construction, the weight of a building increases and it is normal and within safe limits for it to sink several centimeters. But below ground in Dubai there is only loose sand and weak sedimentary rock. Engineers dug 140m deep, still couldn't find solid strata. If normal raft foundation construction is done at this site, it will sink a lot and disaster will surely happen.

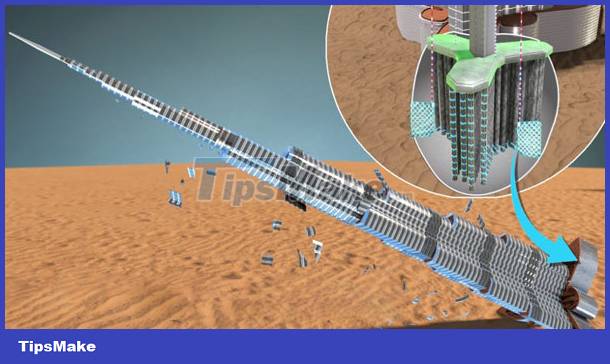

A simple solution to this complex problem has been proposed by chief engineer Bill Baker to use the friction force of the surrounding soil. When Bill Baker pierces the sand with a sharp, thin stick, to a certain depth, the increase in friction generated from the surrounding sand as the stick descends makes it impossible to descend further. To create friction he added RCC piles below the raft foundation with a depth equivalent to 10 stories of Burj Khalifa. When construction is completed, the building only has a settlement of about 5cm, which is quite safe.

In order to build these piles in the best way, realizing this design, the engineers drilled the hole with an excavator with a drill bit. During the excavation process, workers simultaneously pour a drilling fluid into the hole to create a slurry, which creates hydrostatic pressure on the borehole wall to help prevent the soil from collapsing. The workers then placed a temporary hollow steel cylinder to keep the soil intact for the concreting process and then placed it in reinforced steel bars that were welded together like a cylinder. Concrete is poured in with the help of underground concreting pipes. The construction of the foundation of the world's tallest building took up to 2 years.

Another challenge is Dubai's strong sandstorms. The pile foundation design will not withstand strong sandstorms, so the engineers have increased the number of piles in the wings to help the tower withstand wind speeds of up to 240km/h.

Surprisingly, the Burj Khalifa's foundation had to be electrified 24/7 so that saltwater seeping in from the Persian Sea wouldn't wear down the reinforcing bars inside the piles. Any minor problem with the current will weaken the foundation and can lead to tragedy on a windy day.

You should read it

- ★ Surprise with the record of altitude in the world is unknown

- ★ Reviews on the Tower of the Approval - Together 'to the top'

- ★ Pisa leaning tower - The most unique architecture on the planet

- ★ Evaluation of fan quality of Unold 86890 tower of Germany

- ★ The Germans will check elevator safety at the 246m high tower at a speed of 40mph / s in 2017