What is PDCA?

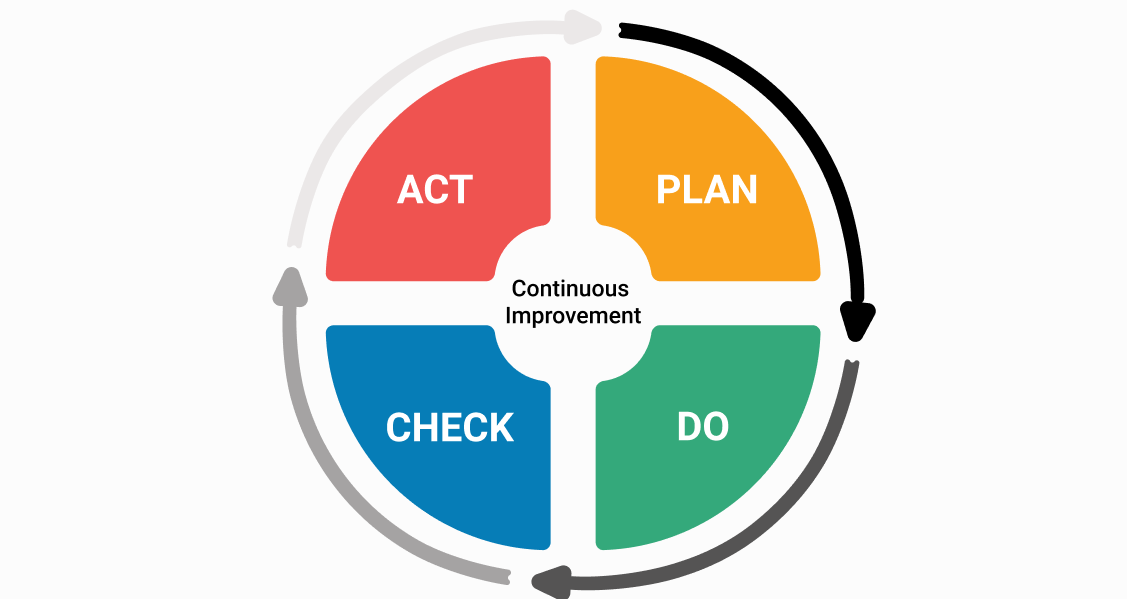

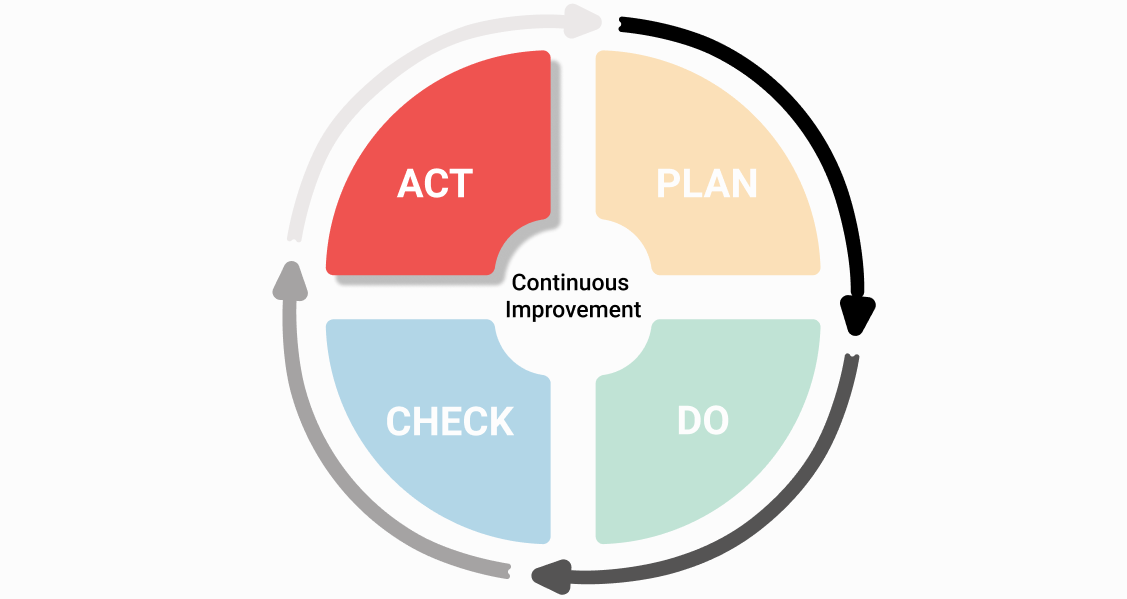

The Plan-Do-Check-Act (PDCA) cycle is an implementation model for change. It is an essential part of lean manufacturing philosophy and is an important prerequisite for continual improvement of people and processes.

First, proposed by Walter Shewhart and then developed by William Deming, the PDCA cycle becomes a broad framework for continuous improvements in manufacturing, management and other areas.

PDCA is a simple four-stage method, helping teams avoid repetition errors and process improvements.

- Kaizen Method: The philosophy of wastefulness and job management of Japanese people

- Efficient time management with the Eisenhower Matrix method: Put your energy into what's important and not urgent

- Pomodoro 'tomato' method: Focused, highly effective work without fatigue

So, where does this PDCA cycle originate?

American statistician and physicist Walter Shewhart is considered to be the father of the PDCA cycle. He is passionate about statistical analysis, quality improvement, and has built the PDCA platform that is documented in many publications.

Years later, inspired by Shewhart's idea, William Deming actually developed the model into a learning and improvement cycle, becoming popular. This is why the model is also known as the Shewhart cycle or the Deming cycle.

What is PDCA?

The PDCA cycle is an iterative method to improve products, people and services. It became an integral part of what is now called lean management. Models include solution testing, results analysis, and process improvement.

For example, imagine you have a lot of customer complaints about a slow response support team. Then you need to improve the way the team works to please your customers. This is the time to use the PDCA cycle.

Let's explore the four stages of the PDCA to find out the details.

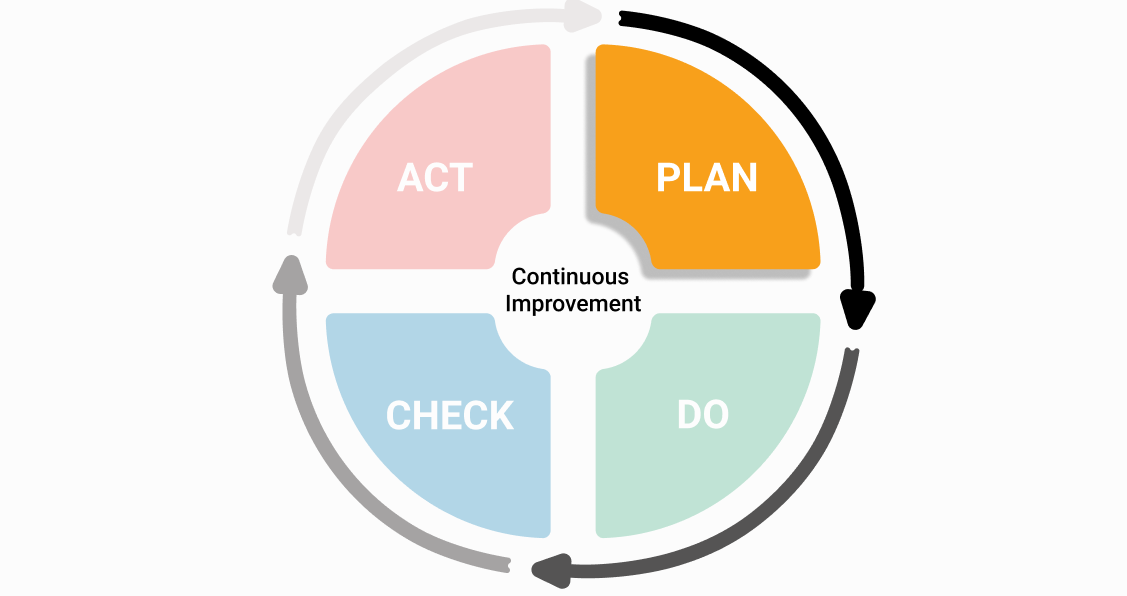

Plan

At this stage, you will plan what to do. Depending on the size of the project, planning may be the most active part of the team. It usually involves small steps, so you can build a plan that is less likely to fail.

Before moving on to the next stage, you need to be sure to answer some of the following basic questions:

- What is the main problem to be addressed?

- What resources are needed?

- What resources are available?

- What is the best solution to troubleshoot with available resources?

- What conditions are considered successful plans? What is the goal?

It is important to note that you and your team may need to approve the plan a few times before proceeding. In this case, you should use a technique to create and maintain an open feedback loop like the Hoshin Kanri implementation policy. It will allow you to gather sufficient information before deciding to proceed.

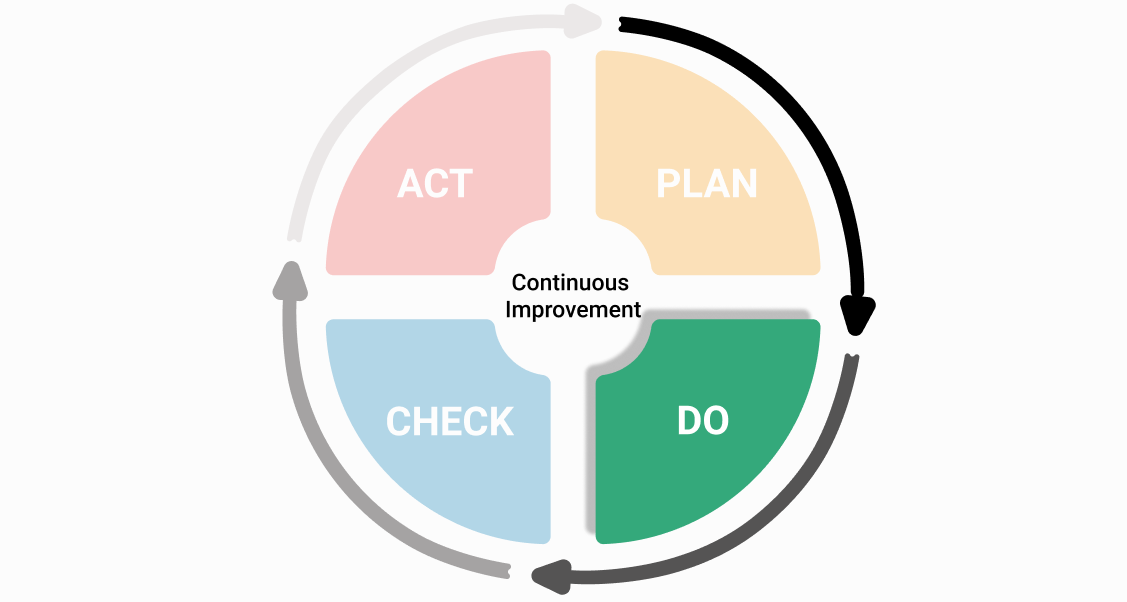

Do (Do)

After agreeing with the plan, it's time to do it. At this stage, you will apply everything that was considered in the previous stage.

However, unforeseen problems may occur during this period. Therefore, to avoid this, you need to try to combine your plan with a small scale and in a controlled environment.

Standardization will help your team apply the plan smoothly. Make sure everyone understands their roles and responsibilities.

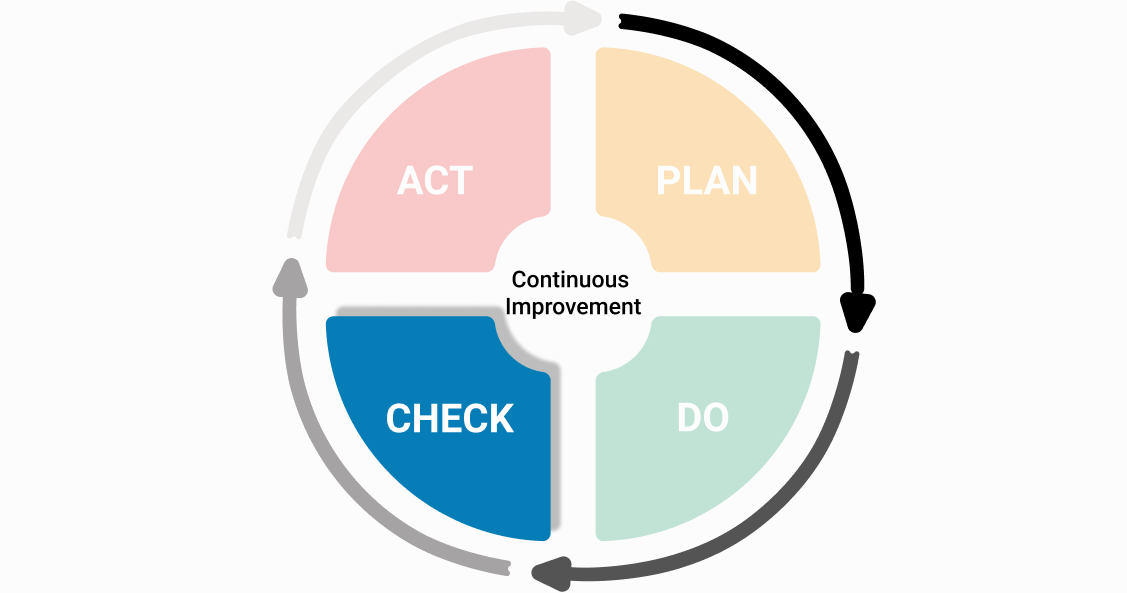

Check

This may be the most important phase of the PDCA cycle. If you want to make your plan clear, avoid mistakes and apply continuous improvement successfully, you need to pay a lot of attention to this TEST stage.

Here, you need to check the implementation plan and see if the original plan is really effective. Moreover, your team can identify problematic sections of current processes and eliminate them in the future. If there is a problem in the process, you need to analyze and find its root cause.

Adjustment (Act)

At earlier stages, you developed, applied and tested your plan. Now you need to make adjustments.

Everything seems to be perfect and your team is trying to achieve the original goal, you can go ahead and apply this plan.

You can apply the whole plan if you meet the goal. The PDCA model will become the new standard baseline. However, each time you repeat the standard plan, remind your team to carefully repeat all the steps and try to improve.

The PDCA cycle is a simple but powerful framework for overcoming problems at any level of the organization. It could be part of a planning process like Hoshin Kanri.

Repetitive methods help your team find and test solutions and improve them.

The PDCA cycle includes a mandatory commitment to continuous improvement and it can have a positive impact on productivity and efficiency.

Last but not least, keep in mind that the PDCA model requires a certain amount of time and it may not be appropriate to address urgent issues.

The Plan-Do-Check-Act Cycle is a useful tool that can help your team solve problems much more effectively. PDCA has some significant advantages:

- Stimulate continuous improvement of people and processes.

- Allow your team to test viable solutions on a small scale and in a controlled environment.

- It prevents the working process from making mistakes again.

What is GPA? What does GPA mean?

What is GPA? What does GPA mean?![[10+] Simple, cheap housewarming gifts for friends and relatives](https://tipsmake.com/data/thumbs_80x80/[10]-simple-cheap-housewarming-gifts-for-friends-and-relatives_thumbs_80x80_no4MS6YCL.jpg) [10+] Simple, cheap housewarming gifts for friends and relatives

[10+] Simple, cheap housewarming gifts for friends and relatives What is doodle?

What is doodle? Admire the award-winning works in the first stock photography contest about hackers

Admire the award-winning works in the first stock photography contest about hackers What is JD? What does JD mean?

What is JD? What does JD mean? Black bean sprouts do anything? Instructions on how to make black bean sprouts at home is easiest

Black bean sprouts do anything? Instructions on how to make black bean sprouts at home is easiest