Why does today's smartphone have a higher resolution than professional cameras and cheaper resale prices?

The technology market is undergoing a huge paradox, professional cameras have a high price but the resolution is only 24MP, 30MP, while many smartphones have a very high resolution of up to 40MP, 48MP is cheaper.

In addition, smartphones also have other functions that the camera cannot have such as high-quality screens, phone calls, Internet access. So why do professional photographers spend a lot of money to buy bulky cameras without using smartphones to take pictures?

Smartphone Huawei P30 Pro with 40MP main camera and Sony A7III camera with Full-frame sensor resolution of only 24MP.

Smartphone Huawei P30 Pro with 40MP main camera and Sony A7III camera with Full-frame sensor resolution of only 24MP.

Image sensor size determines product price

Image sensor size is one of the biggest differences between professional camera lines and camera phones. This is also the most expensive component in a camera.

Compared to the camera's 1-inch, Full-frame or APS-C sensors, image sensors range from 1/4 ″ to 1 / 2.3 ″ on regular smartphones or 1/2 ″ and 1 / 1.7 ″ on high-end smartphones is too small.

The sensor size is proportional to the size of the pixels.

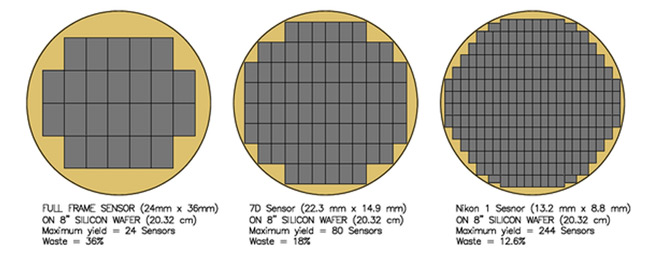

These sensors are cut from a circular wafer. A wafer can only produce 24 Full-frame sensors and 36% redundancy but the same plate can produce 244 1-inch sensors and excess area is only 12.6% or 1200 sensor for smartphones.

The image sensor may be faulty and the risk of an error is directly proportional to the area of the sensor. In a batch of Full-frame sensors with 24 units, there may be up to 10 defective ones This pushes its cost up a lot. Meanwhile, a batch of 1200 smartphone sensors has only 10 defective ones, this error rate is almost negligible.

Large resolution does not determine image quality

So, why don't manufacturers make 100MP, 200MP or 1000MP sensors by adding light-receiving diodes (pixels) to capture microorganisms?

The correlation between sensor size and resolution is the reason for preventing them. If the number of diodes increases, the pixels become smaller. This causes the light sensitivity to decrease, the final image will darken. To lighten them, the device will have to use software but will cause noise and many other errors.

The magnitude of the pixel also affects the ability to pick up colors. While smartphones usually only get 8 bits of color, professional cameras can be up to 12-16 bits. Therefore, smartphones must use software tricks to compensate.

To be able to give the best picture, manufacturers must find a way to balance the resolution and the ability to pick up the pixel's brightness. APS-C or Full-frame sensors with a resolution of 24 - 30MP can give good definition when viewed on screen and printing, while also ensuring good dark shooting capability. Nearby is enough to meet the needs of most photographers. If there is a higher demand, they can also select 40 - 50MP cameras currently available on the market.

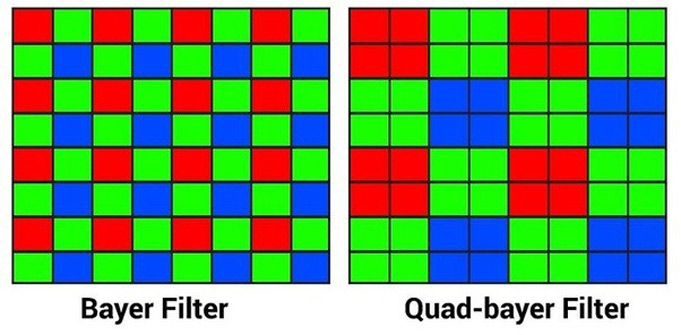

Compare color filter layer Quad-bayer and Bayer.

Image sensors on traditional cameras and smartphones pick up colors through Bayer color filters, with alternating Blue, Blue and Red arrays. For smartphones with up to 40MP or 48MP resolution, image sensors use Quad-bayer filters, placing 4 similarly colored dots close together.

When going through this Quad-bay layer, the 48MP sensor will give a resolution of only 12MP, and a 40MP sensor will give images only 10MP. This helps them gain more brightness in the dark and has a slightly higher definition than the usual 10 - 12MP sensor.

The lens has a great role in the shooting process

The front lens's ability to receive light is also an important factor that determines image quality. With professional cameras, users can change different lenses, even those with a price of a smartphone or a car.

Professional camera lenses are made of high-quality glass, precisely honed and covered with expensive coatings, with good weather-resistant casing and complex motors.

The creation of small-size glass lenses is very difficult and costly, so manufacturers choose plastic to create smartphone lenses.

With professional cameras, photographers can choose to change high quality lenses.

In fact, the definition and resolution of high-quality lenses on professional cameras can hardly achieve the quality that the company claims, there are always certain errors. And with plastic lenses and small sensors on smartphones, this is even more true, with no smartphones achieving a 'true' 40 or 48MP resolution.

Therefore, to increase the quality of photography on different Point & Shoot cameras, the manufacturer only uses large sensors, instead of lens design, not increasing the resolution.

You should read it

- ★ Samsung reveals 108MP camera sensor, designed for Xiaomi phones?

- ★ Megapixel or sensor size is more important for smartphone cameras?

- ★ What is the difference between DPI, PPI, resolution and image size?

- ★ Leica launches M10-R high-end camera: German camera firm with high-resolution battle

- ★ Sony announces today's highest resolution image sensor for smartphones