What does toughened glass do that hard?

Tempered glass is a type of safety-resistant glass that is more resistant to impact, strong impact and heat resistance than conventional glass because it is treated with temperature or chemicals.

- Discover the history and exciting production process of toilet paper

- Did you know: What do auto glass do without breaking when an accident?

My glasses (heating up to about 600 degrees Celsius and sudden cooling with cool air) make the glass surface pressed and the middle glass stretches. This makes the glass safer, when broken it will be separated into small round pieces, not into big pieces.

The glass surface must withstand the pressure of at least 69 megapascals - 10,000 psi, which is equivalent to the pressure at a depth of more than 6,500 meters on the ocean floor (if there is no protective gear, people will be crushed under this pressure. ) new is called toughened glass. And so that glass can break into small pieces to ensure safety, it must withstand the pressure of more than 100 megapascals - 15,000 psi, equivalent to the pressure at the Mariana Trench - the deepest ocean groove the human world has ever known with a depth of 11 km below sea level.

All glass cutting and glass cutting must be done before me to prevent broken glass.

There are 2 types of toughened glass.

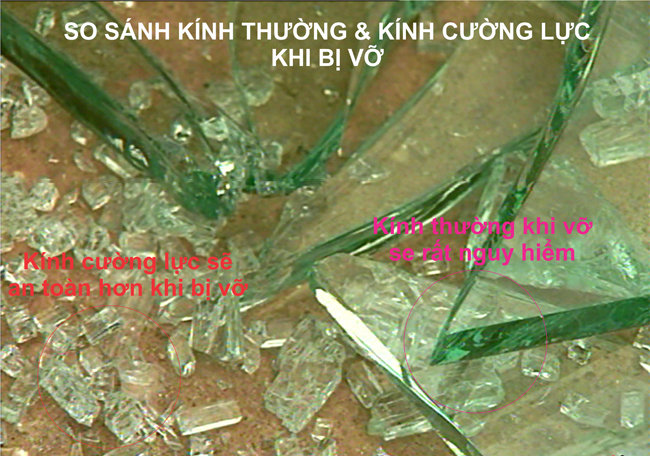

- Semi -tough glass: hardness 2-3 times higher than regular glass. When a strong collision occurs, it will crack from the center and touch the glass frame, not break into a sharp piece like a normal glass.

- Fully tempered glass: hard 4-5 times more than regular glass. When a collision is too strong, it will break into particles like corn grains to prevent damage.

Because of its safety, toughness and toughness nature, toughened glass is used in many different areas from manufacturing auto glass, glass doors to bathrooms, interior decoration to making screens. phone, bulletproof glass, .

Production of tempered glass

Produced by heat

The glass is normally placed on a conveyor belt and passed through a heating furnace between 564 degrees Celsius and 620 degrees Celsius. Immediately afterwards, the glass is immediately cooled by an air blower system. At that time, the new glass surface cools down, but the inner glass is still hot and cooled naturally.

Chemical production

The glass will be pinned to a large potassium nitrate tank so that the elemental sodium ions on the glass surface are at least 0.1mm thick exchanged with the potassium element (because the ion is replaced by potassium greater than 30%). With this method of production, people can produce shapes that are more complex than the method of producing tempered glass.

You should read it

- ★ How to Cut a Tempered Glass Screen Protector

- ★ Did you know: What do auto glass do without breaking when an accident?

- ★ Google Glass has a new boss

- ★ Successfully fabricated flexible glass, which can only be bent, not broken

- ★ Rounded his eyes to see the bullet shatter when shot at the glass of 'Dutch tears'