4 Awesome Things You Didn't Know About Surface Treatment

There are so many things that can be done and when working in environments that are filled with pathogens, cleanliness should be at the top of your priorities. The materials used or the products on the production lines could pose a great danger to your employees.

Such are materials that could also contribute to the overall functionality of the finished product. Surface treatment has become an integral process in most if not all workplaces. Ensuring that you are protected from the most common pathogens can greatly help to keep infections at bay. Below are four awesome things you need to know about surface treatment.

Surface Pretreatment

If you are in the manufacturing industry, then you know all too well how some surfaces can be hazardous to your employees and your clients as well. The manufacturing industry has helped pave the way for so many inventions and not to forget the economic benefits of it. But with it, there are risks involved that can be managed with ease.

Surface pretreatment helps to ensure that the surfaces you are working on are in good working condition. It also prevents devices from failing and you have corona pretreatment systems that will help to guarantee this and much more. There are so many reasons why you might consider such a pretreatment option. For starters, it will help to improve efficiency in your workplace, ensure the longevity of your equipment, and more so, protect your employees from infections.

Thorough Equipment Cleaning

What is the best way to protect your equipment than preventing it from wear and tear? When it comes to production, the equipment used will be your most significant equipment asset. Without such equipment, productivity would go down, and in a way, affecting business. Exposing materials to wear and tear may not cause an immediate problem, but you will experience extreme damages with time.

However, not many know about the best ways on how to prevent such issues. Surface treatment proves vital to the equipment by reducing wear and tear as well as ensuring that such surfaces are clean and free from germs. Solving this problem can significantly and positively influence your productivity. You can avoid repair and replacement costs by ensuring that your equipment is clean. Here's how to achieve this:

- Spraying with insecticides, disinfectants, and ensuring that there are sanitation bays

- Training employees on the importance of cleanliness

- Provide your employees with the proper protective gear

- Ensure that your work environment is free from germs

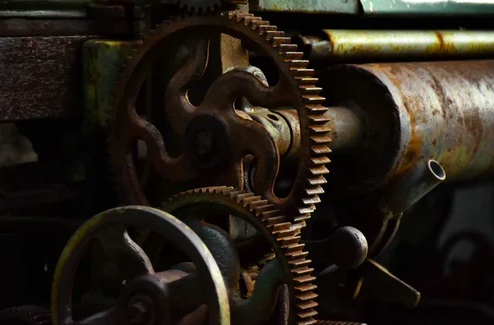

Corrosion Resistance

Corrosion occurs when a metal reacts with substances like an electric current, bacteria, hydrogen, oxygen, or even dirt. It may also happen that when certain substances are exposed to certain conditions, they react differently. The most common type occurs when metals come into contact with water, or oxygen causing rusting. This condition is one of the problems posing a significant threat to the industrial sector.

Manufacturers and engineers report spending a considerable amount of money in combating the menace. What is beneficial about surface treatment is that it works magic on corrosion. Surface treatment minimizes exposure of these metals to oxygen and humidity by slowing down deterioration through the coating.

Less Friction

Friction can be disgusting. It causes surfaces to seize when they come into contact, and this may cause severe problems like work shut down or delay. People face challenges when trying to reduce friction by eliminating factors that cause it. Some make it worse while trying to deal with the issue. It is crucial to understand that metal surfaces have various degrees of roughness, which can only be solved using the proper finishing. Without surface treatment, friction will only slow down moving objects leading to more problems like wearing out of parts.

Prolonged Longevity

The other awesome thing about surface treatment is that it increases the longevity of materials. Coating minimizes and prevents wearing and tearing any further possible damage caused to the equipment. There are countless ways to help increase the longevity of your equipment and such might include regular servicing, and in our case, surface treatment.

You can avoid all this by ensuring that you go for materials that have been treated with the proper finishings. You have engineers who'll provide the right chemicals and materials to offer maximum protection to your equipment from damage.

While surface treatment is essential for many industrial processes, like offering protection to production equipment and protection to employees. Most people have turned to appreciate surface treatment as it provides them with the above awesome benefits.

You should read it

- ★ Surface Book 3 officially launched, becoming the most powerful Surface

- ★ Microsoft is developing a low-cost Surface computer running Windows 11 SE

- ★ Microsoft: Surface Pro 3 sales exceeded expectations

- ★ Experience in controlling gout is effective during treatment

- ★ Microsoft launched the first ad clip of the Surface Pro 3