How to Seal a Plastic Gas Tank

Method 1 of 3:

Seal Plastic Gas Tank with Epoxy Glue

-

Drain the gasoline from the tank and allow it to dry. Sand the area around the hole or crack, and clean the area with a shop cloth saturated with rubbing alcohol.[1]

Drain the gasoline from the tank and allow it to dry. Sand the area around the hole or crack, and clean the area with a shop cloth saturated with rubbing alcohol.[1] -

Mix the 2 part epoxy together and apply all around the perimeter of the opening.[2] Cut a fiberglass patch large enough to cover the opening and overlap it.

Mix the 2 part epoxy together and apply all around the perimeter of the opening.[2] Cut a fiberglass patch large enough to cover the opening and overlap it. -

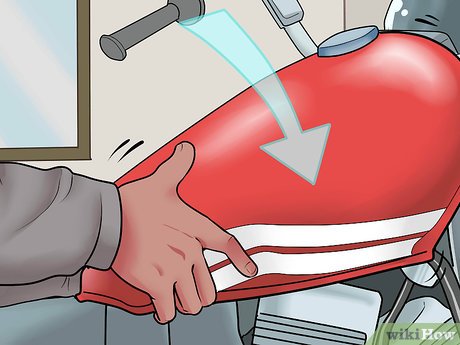

Place the fiberglass patch over the hole and press into the epoxy. Apply more epoxy to the patch and surrounding area, pressing firmly to saturate the patch.

Place the fiberglass patch over the hole and press into the epoxy. Apply more epoxy to the patch and surrounding area, pressing firmly to saturate the patch. -

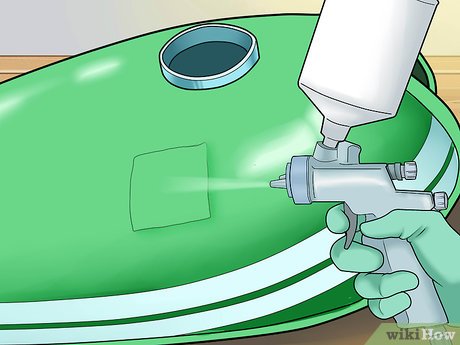

Allow to dry, sand the patched area smooth and spray paint with a plastic paint if desired.

Allow to dry, sand the patched area smooth and spray paint with a plastic paint if desired.

Method 2 of 3:

Seal Plastic Gas Tank with a Plastic Welder

-

Buy or rent a plastic welder. Tell the salesperson what you are doing with it to ensure that you get the correct rods.

Buy or rent a plastic welder. Tell the salesperson what you are doing with it to ensure that you get the correct rods. -

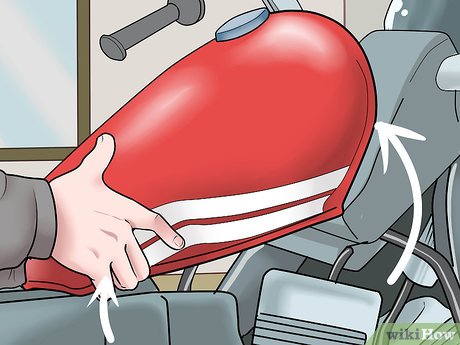

Remove the plastic gas tank from the vehicle, and set it up in a secure welding area. Drain the gasoline from the tank, and allow it to dry both inside and outside. Don protective eye gear, a welding helmet and welding gloves.

Remove the plastic gas tank from the vehicle, and set it up in a secure welding area. Drain the gasoline from the tank, and allow it to dry both inside and outside. Don protective eye gear, a welding helmet and welding gloves. -

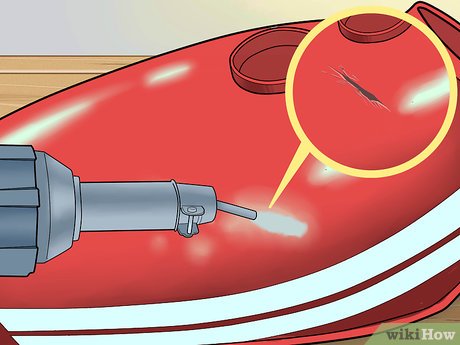

Use a plastic welding rod made specially for this purpose, and fill in the crack or hole. Start at an edge and run the bead completely around the opening. Then begin crossing over the hole, allowing the rod to fill in the hole completely.[3]

Use a plastic welding rod made specially for this purpose, and fill in the crack or hole. Start at an edge and run the bead completely around the opening. Then begin crossing over the hole, allowing the rod to fill in the hole completely.[3] -

Allow the weld to set up, sand it smooth and, if desired, paint it with plastic spray paint.

Allow the weld to set up, sand it smooth and, if desired, paint it with plastic spray paint. -

Replace the repaired plastic fuel tank on the vehicle.

Replace the repaired plastic fuel tank on the vehicle.

Method 3 of 3:

Seal Plastic Gas Tank with a Soldering Gun

-

Drain the gas tank, and clean it inside and out with soapy water.[4] Lightly sand the perimeter of the area to be repaired.

Drain the gas tank, and clean it inside and out with soapy water.[4] Lightly sand the perimeter of the area to be repaired. -

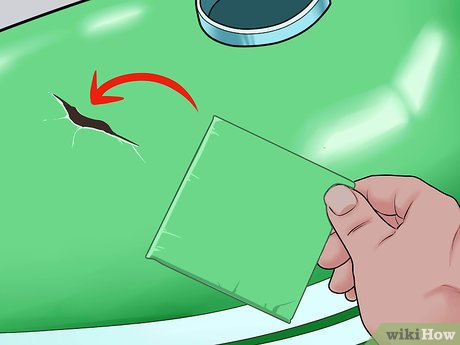

Cut a plastic patch, made of a similar material to the gas tank, slightly larger than the hole to be repaired.

Cut a plastic patch, made of a similar material to the gas tank, slightly larger than the hole to be repaired. -

Heat up an electric soldering gun, and drag it around the edge of the crack to create a trench. Move the gun from side to side to push the plastic back into the trench. While the plastic is still soft from the soldering, lay the plastic patch over the area. Continue moving the soldering gun over the area to smooth the plastic, and fuse them together.[5]

Heat up an electric soldering gun, and drag it around the edge of the crack to create a trench. Move the gun from side to side to push the plastic back into the trench. While the plastic is still soft from the soldering, lay the plastic patch over the area. Continue moving the soldering gun over the area to smooth the plastic, and fuse them together.[5] -

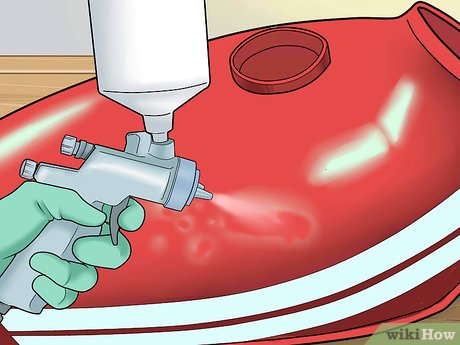

Allow to cool and dry completely. Mix a 2 part epoxy glue, and cover the entire area of the patch.[6] Allow to set up, sand and spray on a coat of plastic paint if desired.

Allow to cool and dry completely. Mix a 2 part epoxy glue, and cover the entire area of the patch.[6] Allow to set up, sand and spray on a coat of plastic paint if desired.

Share by

Samuel Daniel

Update 24 March 2020