Examine the process of turning garbage into street bricks and clothes in Japan

In modern factories in Tokyo, waste types are effectively classified and recycled to serve human life. Let's visit one of the modern waste treatment plants here to know how effective Japanese waste disposal is!

- While many countries are "flooded with garbage", the country is importing waste to use

- Use kitchen garbage to recycle into fertilizer for home vegetable garden

- Incidentally: Used toilet paper can be recycled into electricity

Across the streets of Tokyo, Japan there is always the presence of garbage plastic containers waiting for recycling.Before being taken to recycling plants, the garbage was meticulously classified.

Recyclable plastic containers are gathered to the Minato Resource Recycling Center, in Minato district, Tokyo.Here, garbage is recycled to continue the life cycle in a different form.

The process of sorting garbage is completed by workers.

Minato Resource Recycling Center owns a recycling line for glass waste that has the capacity to process about one ton of glass waste per hour, equivalent to 4,000 bottles.

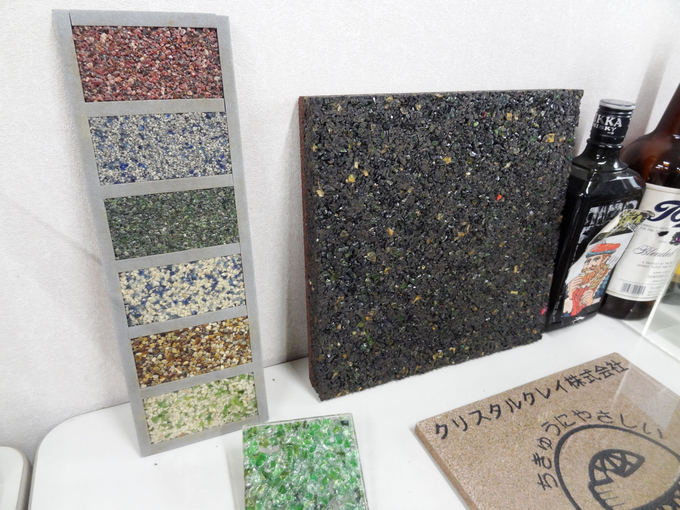

After treatment, the bottle will turn into glass pieces.They will then be recycled into paving materials or reused as bottles.In metal waste treatment lines, magnets are used to classify steel and aluminum.This line has a compressive capacity of 1,400 boxes at the same time.After treatment, metal waste will become the raw material for construction materials, canning industry or automobile manufacturing.

Plastic bottles are compressed into bales for recycling into fibers, office products or new bottles.Lines for compressing plastic bottles made from polyethylene terephthalate (PET) can compress 1 ton per hour.

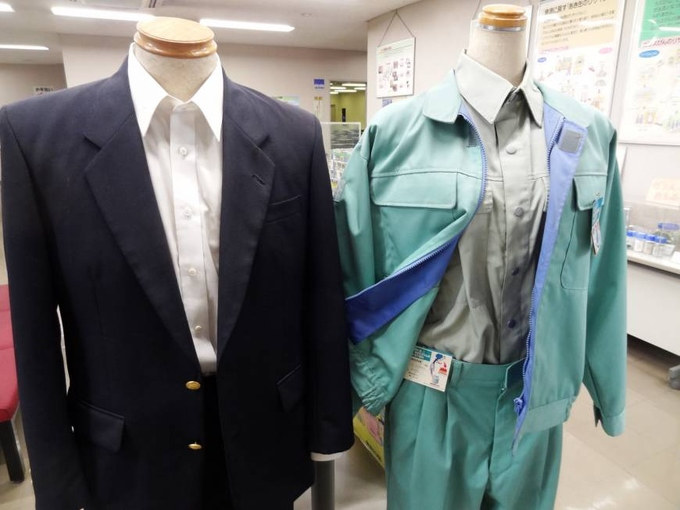

Clothing made from recycled plastic fiber PET is on display at the Minato Resource Recycling Center.Currently, Minato recycles about 29.8% of recycled materials, and it hopes to raise this ratio to 42% by 2021.

PET plastic bottles are gathered at PET Refining Technology Plant in Ogimachi, Kanagawa Prefecture.

Showa Denko gasification plant in Ogimachi, Kanagawa Prefecture, produces about 80 tons of aluminum from about 5 million recycled aluminum boxes each year.Hydrogen generated during the recycling process will be used for acrylic fibers and pharmaceuticals.And CO2 gas is used for bottled water.

Recycled plastic bales at the factory.Recycling plastic waste reduces CO2 emissions, saves energy, creates a positive impact on the environment.

You should read it

- ★ How long does it take waste to decompose?

- ★ Chemical recycling can be a solution to the problem of plastic waste pollution

- ★ Manufacturing electric cables from plastic waste - The great plan for the situation of plastic waste pollution in the world today

- ★ Scientists created a mutant enzyme that 'ate' nearly a ton of plastic bottles after a few hours

- ★ Use kitchen garbage to recycle into fertilizer for home vegetable garden