New materials used in aircraft manufacturing are copied from human enamel

Scientists found that the teeth in our mouths have a lot in common with the giant fangs they found in the skull of a T-rex. This proves that, at the micro level, the basic structure of enamel does not change much over time. Based on this unique design of nature scientists have created new materials that can improve the strength and safety of aircraft.

The artificial materials that humans have created can only have one of two features: resistant to vibration or hard enough. The metals are hard enough, they cannot withstand vibrations and will develop cracks over time. While artificial materials withstand vibration like rubber are not suitable for assembling aircraft.

Special structure of teeth

Our teeth are hard enough to chew and tear food, and they can also withstand vibrations throughout a person's life from chewing, walking, jumping . without cracking. .

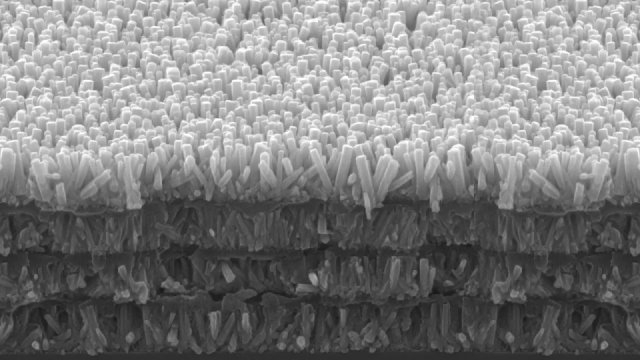

At the micro level, enamel is made up of hardened ceramic crystals and is surrounded by soft organic proteins. When we bite or chew there will be pressure on the tooth, hard ceramic crystal columns are compressed and bent, but thanks to contact with soft organic proteins that help absorb excess energy and do not cause Damage to tooth structure.

Structure of teeth at micro level.

Chemical engineering professor at Michigan Technical University, Nicholas Kotov, who has done research on small changes in tooth enamel through evolutionary times and Bongjun Yeom, a postdoctoral researcher with each creates an artificial material with similar elasticity. They used zinc oxide nanowires surrounded by soft polymer materials to replace soft ceramic crystals and soft protein to create artificial tooth enamel.

This type of artificial enamel is lighter, resistant to constant vibration, high pressure and no cracking . These are the essential properties for use as fuselage, car chassis, and equipment. electronics, even things that are subject to extreme vibrations and G forces like airplanes and missiles.

To produce this artificial tooth enamel, scientists have to make 40 layers of required lengths of only a few micrometres, equal to one-thousandth of a millimeter. And to have enough material to build an airplane would take a very long time, even a year. Therefore, Kotov and his team are still looking for ways to mass produce this material in the near future.

- Fabrication of liquid metal can be self-moving, linked together to create electrical circuits

- Terrified to see the horrid black liquid "creep" into the skull

You should read it

- ★ 10 kinds of 'miracle' materials challenge all laws of physics

- ★ Homemade guide to straight up SU-27 Sukhoi remote control

- ★ Materials can 'self-destruct timer', creating self-erasing ink

- ★ Discovered a new form of carbon, stronger than metal and more resilient than rubber

- ★ Listed the 16 most expensive materials in the world