Find out the mechanism of producing solar cells by enzyme of papaya

Thin-film titanium dioxide (Titania) is a substance commonly used in various types of solar cells. The current methods being used to make Titania are qualified for industrial use that requires high temperatures, as well as advanced, and extremely expensive technologies. This is also one of the reasons why solar cells are expensive, difficult to reach the majority of users.

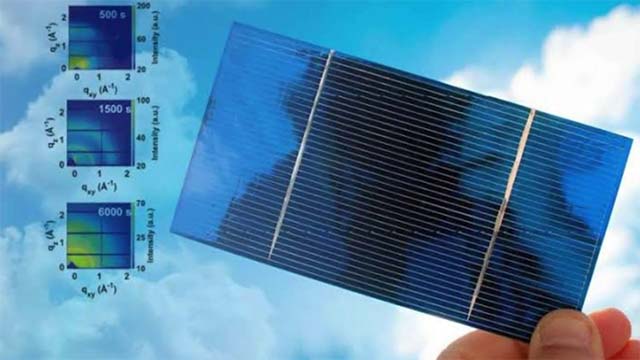

Recently, however, researchers at Delft University of Technology (TU Delft) have successfully developed a method of making thin, porous Titania films at relatively low temperatures, competitive costs, and in particular based on on a completely organic mechanism.

By inserting an enzyme called papain, which is commonly found in papaya, into a relatively simple dipping process, scientists were able to create thin organic titania films. Specifically, 'heating up organic materials in common ovens, so that they evaporate has titania membranes with porous structures', explains Dr. Duncan McMillan, one of the team members.

Quality assurance

From this new manufacturing process, the researchers created the first experimental products: dye-sensitized solar cells.

Conventional manufacturing methods require powerful vacuum systems or specialized equipment to heat the battery sample at a temperature of 600 ° C. This is not only complicated and costly, but also creates layers that cannot be stacked, significantly reducing the surface area of the panel. While the new method proceeds in the opposite way. By depositioning the enzyme for a few minutes, then using a standard oven to trigger the necessary evaporation, the scientists achieved amazing results - with at least 50 Titania layers folded up. overlap. Not only that, the Titania layers also have a very high porosity, thereby giving a larger surface area. The team believes that this will bring about greater efficiency in solar cells when combined with existing technologies. "

Memania membrane of solar cells

Memania membrane of solar cells Production costs drop significantly

Thanks to its simple production process and the ability to scale easily, the new method has opened up the ability to sustainably produce low-cost solar cells that can be widely used in many locations. like on people's houses, or windows of offices.

The team's goal for the foreseeable future is to improve the efficiency and stability of solar cells by using different dyes and adjusting the porosity of the Titania layers.