Winnow uses computer vision to help cut waste in food processing

You may not know it yet, but according to the United Nations Food and Agriculture Organization (FAO), there are about three-quarters of the food produced globally each year never reach the human table, that is. It is about 1 trillion dollars of edible food but eventually 'landed' at the landfill. The restaurant-hotel industry alone contributes about 10% of them. Facing this situation, the Winnow technology solutions team has the idea of computer vision application (machine vision) and machine learning to help reduce waste in food processing.

- Admire Nvidia's new AI application: Turn MS Paint-style doodle into an artistic 'masterpiece'

Founded in London in 2013, so far, Winnow technology has been applied and deployed relatively effectively in the kitchen sector, including as a tool to act as a scale placed below. The kitchen scraps garbage container, which helps gather information about the amount of food that has been discarded after the cooks enter the product information they threw in the trash on a touch screen.

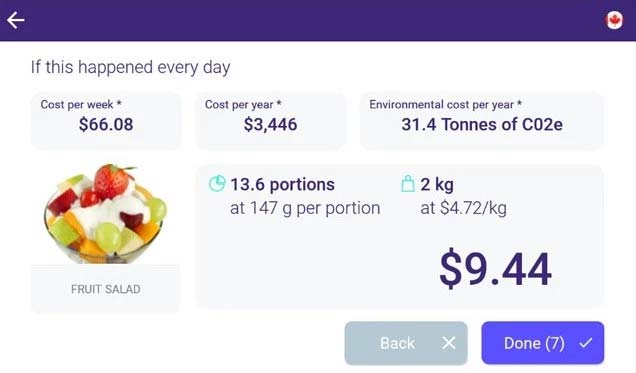

This information will then be transferred to Winnow's cloud-based analysis system, to determine the value of the food that has been discarded, and to produce detailed reports that often raise distraction. fees as well as economic benefits that people can get through cutting waste in food processing every day.

However, Winnow's system until now still needs a much larger and more detailed manual input, which means that the chef has to say more clearly about the types of food they have handled, This is really complicated and time consuming.

To solve the problem, Winnow is currently introducing mixed automation methods, using a combination of artificial intelligence with a computer vision sensor camera, which can automatically capture images of garbage. When poured into a box, and then, machine learning technology will be responsible for analyzing and showing what kind of food it is, how valuable it is.

- AI uses WiFi data to estimate the number of people in a room

Training machine learning model

Although the theory is like that, in fact this system does not work perfectly perfectly - it can identify many different fruits and vegetables, but still have to "wrestle" in the body. define more 'obscure' items, such as different types of meat! That is why chefs and kitchen staff still need to join hands with developers in training this machine learning system. For example, employees may be asked to choose the food item they have discarded from the list displayed on the touch screen. According to experts' estimates, it will take 200 to 1,000 images only to train the Winnow Vision machine learning system that can recognize a food item.

- Google and DeepMind apply AI to predict the output of wind farms

In some related moves, Winnow Vision has previously been used as part of several pilot projects with several major brands since January last year, including the Swedish Ikea group, in aims to cut the amount of food waste in this enterprise by half in general.

'We have set ourselves an ambitious goal to cut food waste by up to 50% in all processing operations, and will accomplish this task by September 2020. Cooperation Ikea's part with Winnow is a very important part to realize that goal. "We know that food waste is causing a huge waste and cutting this waste is not a simple matter, but Winnow has proven that they have solutions to solve problems. in a really effective way, 'said Hege Sæbjørnsen, managing director of Ikea UK and Ireland.

Other large businesses participating in the testing phase include the UK Morrisons and Emaar supermarket chains in the United Arab Emirates. However, from today, Winnow Vision will be available globally and can be used in all restaurants and kitchens around the world.

'Food waste is a global problem facing humanity. Not only does it relate to the problem of wasting money, but also more important environmental pollution also entails other food security issues. And every kitchen, processing line around the world is having a 'headache' to cope with food waste. Therefore, without proper management tools, it is difficult for businesses to realize how much they are wasting and how much money can be saved by using food more effectively. . By using AI to analyze and specifically report on food waste, as well as actual costs - Winnow Vision will be a powerful assistant in a modern kitchen, food processing line, ' CEO Winnow Marc Zornes said.

- Google AI application in detecting eye diseases

Benefit of economic

Winnow applies the model to this software as a service (SaaS), which means the subscription fee for accessing monitoring software. Although it does not disclose the specific price for each service package, but according to calculations from this company, the catering service providers can expect the possibility of a payback of 2-10 times right away. In the first year, saving up to $ 50,000 should have been lost due to waste-related problems during food processing.

'Thanks to the use of artificial intelligence technology that is specifically about machine learning with the ability to self-learn and improve after each use, Winnow Vision is capable of handling problems with food waste above. Global scale ', CEO Marc Zornes shared.

- AI engineer Facebook talks about deep learning, new programming languages and hardware for artificial intelligence

Besides Winnow, there are also a number of startups operating in the field of providing different solutions to help reduce waste during food production and processing. A Swedish company called Karma mobilized a capital of up to $ 12 million last year in building a market that encourages restaurants and supermarkets to sell their surplus food - probably Freshly squeezed pastries, breads, or fruit juices - at a more favorable price, instead of throwing them in the garbage can cause huge waste.

Another San Francisco-based company, Full Harvest, has recently mobilized $ 8.5 million in investments to help support the output of faulty products from US farms.

Going back to Winnow's project, the company representative said their current manual system has been used by thousands of chefs in more than 40 countries, and has helped save the equivalent of $ 30 million. It is a waste of food during processing.

For ordinary people, Winnow can be described as a great AI application development company, but in essence, this is a data company - data that allows kitchens and production lines. The output looks wasteful in its operations, and that's what opens up the value of hardware.

If successfully applied, the Winnow Vision project shows that billions of dollars wasted in food processing are completely manageable, this is not only an economic benefit, but It is also an important factor contributing to ensuring global food security.